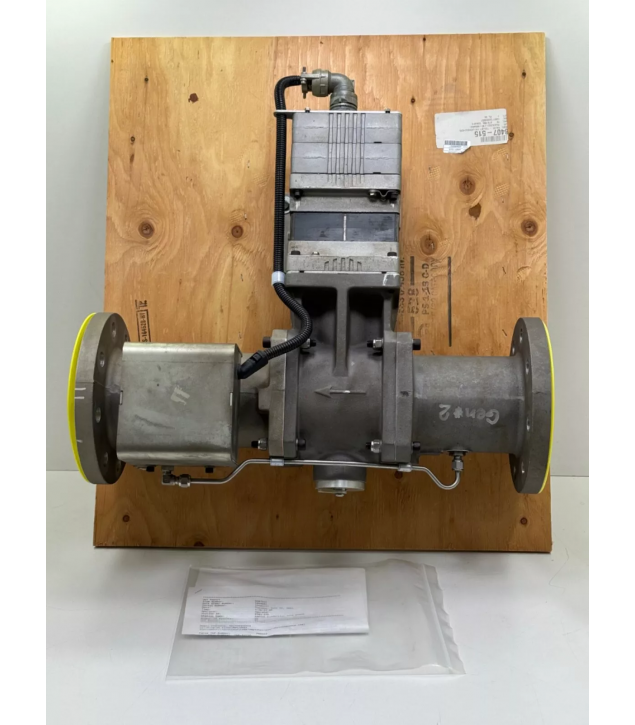

Woodward TecJet110

Overview

The Woodward TecJet110 is a high-performance fuel metering and control system designed for gas turbine engines in power generation, aerospace, and industrial applications. It provides precise fuel flow control, ensuring optimal engine performance, efficiency, and emissions compliance across varying operating conditions.

Key Features

- Precision Fuel Metering: Utilizes advanced servo-valve technology to deliver accurate fuel flow control within tight tolerances, ensuring stable engine operation.

- Digital Control Electronics: Features a microprocessor-based control system with advanced algorithms for real-time adjustment of fuel flow based on engine demands.

- Wide Operating Range: Capable of handling a broad range of fuel pressures and flow rates, making it suitable for diverse turbine applications.

- Fail-Safe Design: Incorporates redundant sensors and control circuits with built-in diagnostics to ensure reliable operation and safe shutdown in case of faults.

- Compatibility with Multiple Fuels: Designed to work with natural gas, diesel, kerosene, and other liquid and gaseous fuels, providing flexibility for different operational environments.

- Integrated Protection Features: Includes over-pressure, over-temperature, and flameout protection to safeguard the engine and surrounding equipment.

- Remote Monitoring & Control: Supports communication interfaces for remote monitoring, diagnostics, and system integration with plant control systems.

- Compact & Rugged Design: Engineered for harsh environments with vibration resistance, thermal stability, and protection against contaminants.

Technical Specifications

| Parameter | Specification |

|---|---|

| Fuel Flow Capacity | Up to 110 gph (416 lph) for liquid fuels, up to 1,500 scfm (42.5 m³/min) for gaseous fuels |

| Inlet Pressure | Up to 600 psi (41 bar) for liquid fuels, up to 150 psi (10.3 bar) for gaseous fuels |

| Pressure Regulation Accuracy | ±0.5% of setpoint |

| Control Response Time | <50 ms for step changes |

| Operating Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Power Supply | 24V DC ±10%, 500mA max |

| Communication Interfaces | Modbus RTU, Profibus DP, Ethernet/IP, analog I/O (4-20mA, 0-10V) |

| Weight | Approximately 18 kg (40 lbs) |

| Dimensions | 450mm x 300mm x 200mm (17.7" x 11.8" x 7.9") |

| Certifications | CE, UL, CSA, ATEX, IECEx |

Typical Applications

- Industrial gas turbines for power generation

- Aeroderivative gas turbines for mechanical drive applications

- Aviation auxiliary power units (APUs)

- Marine propulsion systems

- Oil & gas pipeline compression stations

- Cogeneration and combined cycle power plants

System Compatibility

The TecJet110 is designed to interface with:

- Woodward MicroNet™ and Speedtronic™ control systems

- Third-party engine control systems via standard communication protocols

- PLCs and DCS systems for plant-wide integration

- Remote monitoring and diagnostic platforms

- Fuel management and conditioning systems

Installation & Maintenance

Key installation and maintenance considerations:

- Mounting options: Direct mounting on engine or separate enclosure

- Easy access to serviceable components for routine maintenance

- Pre-calibrated modules for simplified replacement and reduced downtime

- Recommended maintenance interval: 20,000 operating hours or 2 years

- Compliance with ISO 9001 quality standards